How To Put Led Lights Up In Corners

InStyle'south LED tape offers you lot more flexibility than other forms of lighting. You can fit it to curved surfaces, twist information technology and fifty-fifty loop it back on itself. (After all, information technology'due south supplied on reels!)

So bending your LED strip lights for installation on a curved surface is very straightforward. But what if your projects needs its LED record to be aptitude flat (beyond the PCB'southward edge), as in the picture below?

1. How to bend your LED tapes laterally

When we talk almost 'bending LED tapes laterally', it means creating a curve of low-cal on a flat surface (by bending the strip across the edge of the PCB). Like this:

LED strips are designed to exist very flexible. Their PCBs (printed excursion boards) are so robust that many LED tape products can be bent upwards to 90 degrees with no difficulty.

Merely exist enlightened that higher-ability LED strips are less flexible than lower-power ones. This is because the LED modules are placed closer together on high-power strips, and crave wider PCBs (for more rut dispersal).

The v-watt white LED tape shown here has 60 LEDs per metre, mounted on an 8-millimetre-wide PCB.

For comparison, we've got pictures illustrating the flexibility of some more LED tapes below…

Note: When bending your LED tape across the PCB's edge, accept care not to damage the PCB mounting. Nosotros strongly recommend y'all apply the bend at 1 of the tape's marked cut-points.

2. How to bend your LED tapes laterally with clip-on connectors

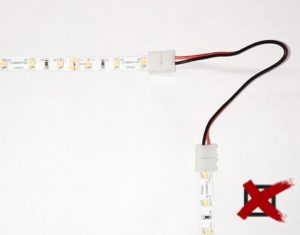

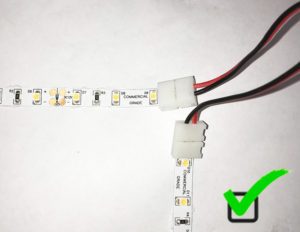

If your LED record needs to bend at an angle greater than 45 degrees (for example, to go around a right-angle corner), then nosotros do not recommend physically bending it. Instead, we suggest i of our tape connectors.

Clip-on connectors have a standard 150mm cable. This length cannot be adjusted, so you'll have to find infinite to hide any excess cable. This can be a problem for some installations.

InStyle'south LED tape has a broad beam angle of 120 degrees, so it tin can be quite forgiving if the LEDs are not perfectly positioned. But even then, be careful non to space the LED strip sections as well far autonomously similar and then, as this will lead to 'dark' patches in the light produced by the LED tape run.

This video explains more than about our clip-on tape connectors.

Instead, you should position the LED strip sections shut together. The goal is to continue an even amount of space between the LEDs on the boards, like and so:

3. How InStyle can solder flexible links so your LED tapes curve laterally

You can order your tape with flexible LED strip connectors already fitted. Tell us where y'all want your tape to curve, and we'll cut and solder your flexible connector(southward) before your order is dispatched – so it's ready to employ right out of the package.

Link cables are completely customisable, and so they can be cut to fit your LED strip lighting project exactly – without excess cable, or with longer cables if required.

Similar this:

Share this folio!

Source: https://www.instyleled.co.uk/support/how-flexible-is-led-tape/

0 Response to "How To Put Led Lights Up In Corners"

Post a Comment